• Series LR rollers are also called CAM ROLLERS, can be used in the heavy loads track or used as an idler wheel. They are widely used in the particular application that the friction should be reduced.

• The outer diameter surface of rollers is shaped to the crowned runner surface with R500 (suffix U), so make the stresses well when rollers working.

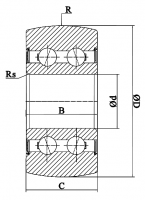

• Rollers take the internal structure design of deep groove ball bearings or double row angular contact ball bearings and have a particularly thick-walled outer ring, so the rollers can accommodate higher loads.

• Rollers are made of the high-quality bearing steel, processed by heat treatment and precision grind, and are filled with a long service life, high -grade and multi-purposes grease. Rollers take the metal shield (suffix KDD) or rubble seal (suffix NPP) to prevent the dust.

Characteristics of the guide system that series LR rollers are applied :

1. Low resistance, long service life, widely-use

Being cam rollers with crowned runner surface R500, make its stresses in well-distributed between rollers and track when working, thus the stresses centralization are avoided, the friction resistance are reduced and the service life of rollers have been improved a lot. Most of the double row cam rollers can be relubricated through the filling hole on the inner ring to adapt the adverse working conditions.

2. Easy installation

After rollers assembled the concentric or eccentric pivot, installation can be made convenient. To adjust the eccentric one's eccentricity, the rollers can get the fitting preload.

3. Smooth running, minimum error

Besides we produce the series LR cam rollers according to the standard of rolling bearings, we also make the strict control on the rotary accuracy of outer ring in order to meet special working mode that inner ring is fixed while outer ring running.